How We Raise Pigs

Although we have grown over the years, Tosh Farms remains a family-owned company. Sensible business strategies, the incorporation of new technology, and the adaptation of modern day health and production practices has allowed us to become the largest pork producer in Tennessee. Read on for a peek into pork production at Tosh Farms.

“[Our employees] are responsible for providing excellent care to these animals every day. And as a company we rely on all of our caregivers to live that mission every day.” – Dr. Seth Krantz, Veterinarian for Tosh Pork

Genetics and Reproduction

The incorporation of elite genetics into our herds is how we maximize productivity and feed efficiency. We partner with the Pig Improvement Company (PIC) to multiply their genetically superior animals. We maintain a herd of PIC boars that are the sires of all of the pigs that we market. We utilize their genetics through the process of artificial insemination.

Production Phases

Breeding

The purpose of the sow farm is to produce healthy, high quality pigs that are raised in our wean-to-finish barns. Sows become pregnant through artificial insemination.

This practice allows us to use vastly fewer boars for breeding than natural mating would require. Because fewer boars are needed, only the best boars are utilized.

After insemination, sows become pregnant and enter into the period referred to as gestation. During their approximately 114-day gestation period, sows are monitored very closely and are housed in either individual or group pens. You can learn more about sow housing here.

No matter what their specific housing situation, we provide each and every one of our sows with excellent nutrition and a comfortable, controlled environment.

Farrowing House

After completing the gestation phase, sows are moved to a specially designed barn called the farrowing house to deliver their piglets.

Farrowing is the term that we use when sows give birth. A farrowing house contains individual farrowing stalls that are specially designed to reduce piglet injury and piglet death which can occur when a sow accidentally lays on one of her piglets.

The sow and her babies require different environmental temperatures to thrive, so we provide our baby pigs with extra heat sources such as heat mats or heat lamps to help them maintain their optimal body temperature.

Piglets

Specially trained personnel act as midwives during the farrowing process and provide assistance to any sows experiencing difficulty giving birth as well as ensure that the piglets are warm, dry, and receive a belly full of milk soon after they are born.

Piglets are born iron deficient so they also receive iron supplementation shortly after birth.

Once pigs are off to a strong start, they are observed daily to ensure that they are healthy and growing at the proper rate.

Nursing & Weaning

During the approximately 21-25 days that they are nursing, they will receive vaccines to protect them from diseases later in life. They may also undergo minor surgical procedures such as tail docking and castration which limit future injury and improve pork quality.

While nursing, the sows are provided with as much feed as they want enabling them to produce as much milk as possible to feed their piglets.

Piglets & Sows Transition

At the end of the nursing period, the piglets are weaned from the sow and transported to one of our wean-to-finish farms to begin the growing phase.

The sows return to the breeding barn to start the process over again. Sows naturally come into heat, meaning they ovulate and are ready to be bred, approximately 4-7 days after their piglets are weaned.

About Wean-to-Finish Farm

Our wean-to-finish farms are specially designed to meet the needs of the newly weaned pig. They utilize brood heaters to provide a zone of extra heat similar to what the pigs were used to in the farrowing house.

Extra water sources are provided to help the pigs as they transition from a diet of milk to plant-based food. Caregivers work with trained pig care specialists to ensure that all pigs receive thorough observation and proper treatment if they become sick.

Multiple times a day, pigs are given extra feed on special mats in their pens to entice them to begin eating this new food source. If pigs are not eating as well as they should be, they are placed in a hospital pen where they are given a specially formulated feed mixed with water and other nutrients with the consistency of an oatmeal-like gruel which further encourages them to eat.

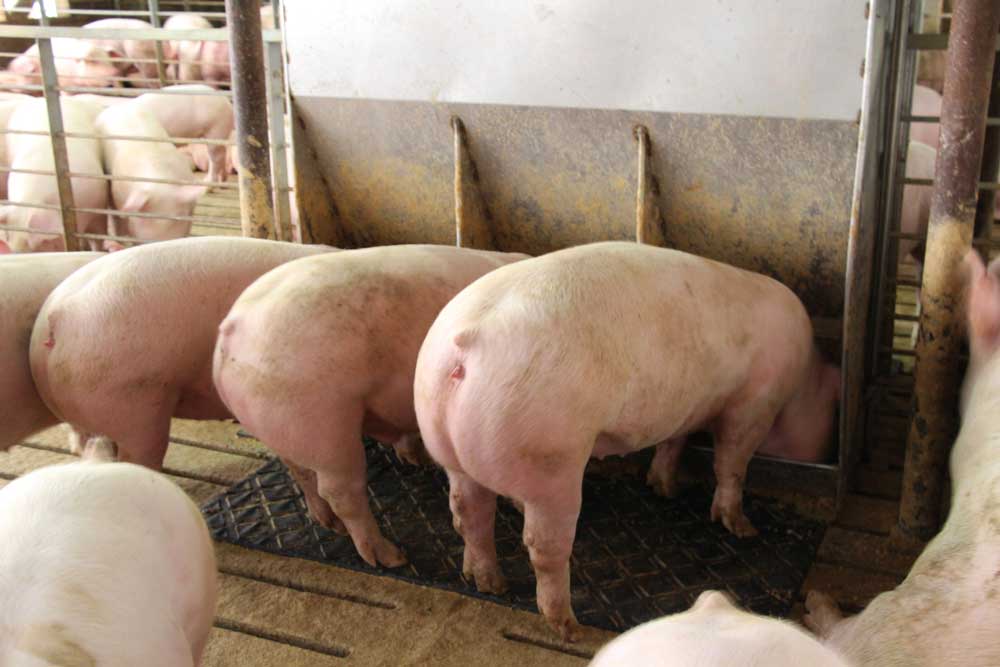

Growth

Within a week of weaning, pigs are off to a great start and have transitioned well to eating plant-based feed.

From this point on, caregivers continue to observe the pigs daily and give individual attention and/or treatment to pigs that require it.

Because all pigs grow at slightly different speeds, they do not all reach the ideal market weight at the same time. The fastest growing pigs typically reach ideal market weight, approximately 285 pounds, around 130 days post weaning and are loaded on a trailer and sent to the harvest facility.

Market

Over the following 4-5 weeks, the remaining pigs reach market weight and are sent to harvest.

When all of the pigs have been marketed, the barn is thoroughly power washed, from top to bottom. Disinfectant is applied to all surfaces of the barn to remove any bacteria or viruses that remain from the previous group of pigs and the barn is allowed to dry. Within a week of all pigs being marketed, a new group of weaned pigs will be brought to the clean, dry barn to begin their growth phase.